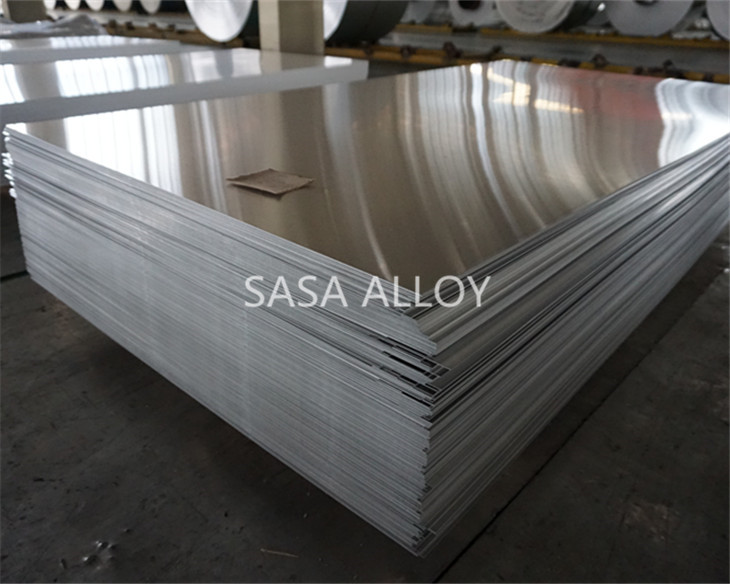

5083 Aluminium Plate

Aluminium Alloy 5083 plate is known for exceptional performance in extreme environments. Aluminum 5083 Plateis highly resistant to attack by both seawater and industrial chemical environments. Alloy 5083 also retains exceptional strength after welding. 5083 Aluminum Plate has the highest strength of the non-heat treatable alloys but is not recommended for use in temperatures in excess of 65 °C.

Typical Applications require a weldable alloy of high to moderate strength, with good corrosion resistance. Marine applications, unfired welded pressure vessels, TV towers, drilling rigs, transportation equipment, Aluminum Armor plate 5083.

5083 Aluminium Plate ASTM B209, ASTM-B-209, EN573, and EN485 international standards.

5083 AMS 4051 Plate, AMS 4051 7178-0 Alclad Plate, QQ-A-250/15 T0, 7178 A95083 Aluminum Plate

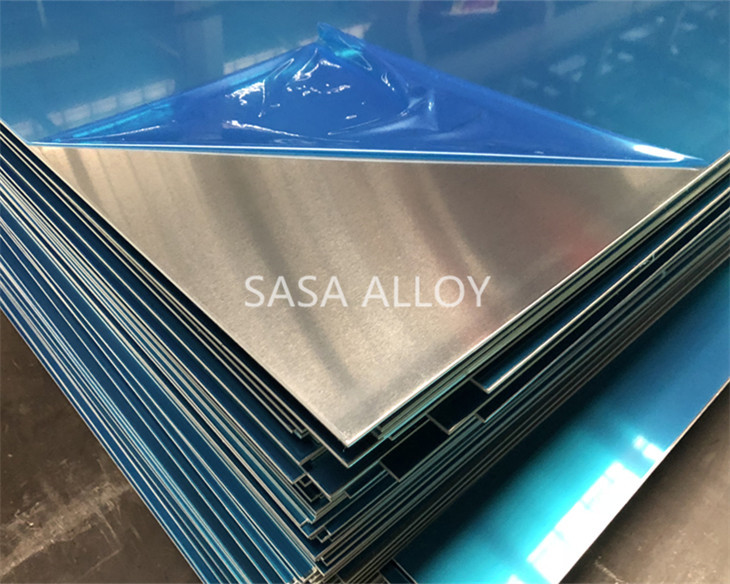

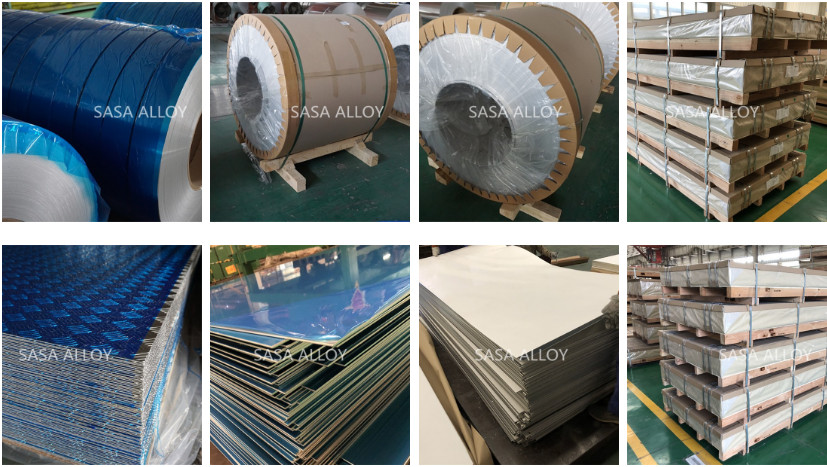

Sasa alloy is the leading manufacturer and exporter of 5083 Aluminium Plate. Supplier of ASTM B209 5083 Aluminium Plate from 0.5mm to 5mm Thick 1000mm x 1000mm to 2500mm x 1250mm Tempers manufactured in accordance with international standards ASTM B209, ASTM-B-209, EN573, and EN485, check 5083 Aluminium Plate price. The general widths of 5083 H16 Aluminum Plates are 1000mm, 1250mm and 1500mm, while common lengths are 2000mm, 2500 mm and 3000mm respectively. Wholesale Trader of 5083 Commercial Aluminium Plate offered by Sasa alloy , China. Stockist of 5083 Aluminium Plate, H32 5083 Aluminium Stucco Plate, H38 Commercial 5083 Aluminium Plate, ASME SB209 5083 Aluminium Patterned Plate, 5083 Mill Finish, 5083 Aluminium Extruded Plate, 5083 Aluminium Plate and 5083 Aluminium Plate in China.

5083 Aluminium Plate Suppliers in UNS A95083 Aluminium Plate stockist in China, 5083 Aluminium Corrugated Plate Suppliers in Best Price of EN AW 5083 H14 Aluminium Plate

You may intrested in:

- 5083 Aluminium Chequered Plate

- 5083 Aluminium Checker Plate

- 5083 Aluminium Diamond Plate

- 5083 Aluminium Tread Plate

Standard Dimensions of 5083 Aluminium Plate

Standard dimensions (a x b) of Aluminium 5083 Plate

Aluminium 5083 Plate up to 9.9 mm

2.000 x 1.000 mm

2.500 x 1.250 mm

3.000 x 1.500 mm

Oversize Aluminium 5083 Plate

4.000 x 2.000 mm

6.000 x 2.500 mm

8.000 x 2.500 mm

Other dimensions on request

5083 Aluminium Plate Suppliers in China, 5083 Aluminium Plate Supplier Singapore, Dealer & Distributor of All 5083 Aluminium Alloy Plate Grades, Stockholder of 5083 Aluminium Plate 1mm

| Aluminium Alloy | ASTM B209 5083 |

| Aluminium 5083 Plate Temper | O, H12, H14, H16, H18, H22, H24, H26, H32, H112 |

| Aluminium 5083 Plate Thickness | 0.5mm-150mm |

| Aluminium 5083 Plate Width | 500-2000mm |

| Aluminium 5083 Plate Length | to clients’ requirement |

| Aluminium 5083 Plate Coating | Polyester, Fluorocarbon, polyurethane and epoxy coating |

| 5083 Aluminium Plate Coating finish | PVDF, POLYESTER(PE) |

| Aluminium 5083 Plate Surface | Polished, hair line, brush, sand blast, checkered, embossed, etching, etc. Mill finish, Bright finish, paper interleaved, one side film, both sides film. |

| Aluminium 5083 Plate Gloss | Meet the customer requirement |

| Total coating thickness of Aluminium 5083 Plate | PVDF coating: More than 25 micron; Polyester coating: More than 18 micron |

| Aluminium 5083 Plate Coating hardness | (pencil hardness) more than 2H |

| Aluminium 5083 Plate Coating adhesive | No lower than1st grade |

| Aluminium 5083 Plate Impact resistance | No cracking or peeling (50kg/cm, ASTMD-2794: 1993) |

| Aluminium 5083 Plate Flexibility (T-bend) | 2T |

| Aluminium 5083 Plate MEK resistance | More than 10 |

| Available Aluminium 5083 Plate Stock Sizes | 1ft x 1ft, 1ft x 2ft, 1ft x 4ft, 2ft x 2ft, 2ft x 4ft, 4ft x 4ft, 4ft x 8ft, 4ft x 10ft or Cut to Size or Custom Shape. |

| Aluminium 5083 Plate Delivery Time | 30-60 days after receiving the prepayment |

| Aluminium 5083 Plate Packaging Details | Standard export package. One pallet is about 2-3 ton.Two steel belts in width and three in width. One 20GP container can load about 18-20 tons Aluminium 5083 Plate. One 40GP container can load about 24 tons Aluminium 5083 Plate |

| ASTM B209 Alloy 5083 Plate Outer packing | Export standard, wooden pallet |

| Bottom side Aluminium 5083 Plate is coated with protective polyester material, thickness more than 6 micron | |

| We Export Aluminium 5083 Plate to | Singapore, Indonesia, Ukraine, Korea, Thailand, Vietnam, Saudi Arabia, Brazil, Spain, Canada, USA, Egypt, Iran, China, Kuwait, Dubai, Oman, Kuwait, Peru, Mexico, Iraq, Russia, Malaysia, etc. |

5083 Aluminium Plate Products Show:

| 5083 Aluminium Plates Product Range | ||||

|---|---|---|---|---|

| Alloy No. | Thickness (mm) |

Width (mm) |

Length (mm) |

Temper |

| 5083 Aluminium Plate | 0.2-5.0 | 20-2200 | 20-8000 | O, H12, H22, H14, H16, H18, H24, H26 |

Standard Specification of 5083 Aluminium Plate

Standards and specifications by country

| Type of plate | Alloy designation | Temper | Mechanical properties | Availability (mm) |

|||||

|---|---|---|---|---|---|---|---|---|---|

| According to EN | According to DIN | According to PN | Chemical | Rm (min) (MPa) | Rp0,2 (MPa) |

Hardness (HB) |

|||

| Cast sawed mould plates (rough surface intended for machining) | ENAW 5083 | 3.3547 | PA13 | AlMg4,5Mn0,7 | Soft | 250 | 120 | 75 | Stock 20-300 |

| Cast sawed precision milled plates (machined surface, protective foil on the both-sides) | ENAW 5083 | 3.3547 | PA13 | AlMg4,5Mn0,7 | Soft | 250 | 120 | 75 | Stock 5-120 |

| Rolled plates (common rolled surface) | ENAW 5083 | 3.3547 | PA13 | AlMg4,5Mn0,7 | Soft | 250 | 120 | 75 | Stock 5-100 |

5083 Aluminium Plate Sizes

| Sizes (mm) | Theoretical Mass KG/Plate |

|---|---|

| 2000 X 1000 X 0.5 | 2500 X 1250 X 0.5 |

| 2000 X 1000 X 0.7 | 2500 X 1250 X 0.7 |

| 2000 X 1000 X 0.9 | 2500 X 1250 X 0.9 |

| 2000 X 1000 X 1.2 | 2500 X 1250 X 1.2 |

| 3000 X 1500 X 1.2 | 2000 X 1000 X 1.6 |

| 2500 X 1250 X 1.6 | 3000 X 1500 X 1.6 |

| 2000 X 1000 X 2.0 | 2500 X 1250 X 2.0 |

| 3000 X 1500 X 2.0 | 2500 X 1250 X 2.5 |

| 2.79 | 4.36 |

| 3.91 | 6.10 |

| 5.02 | 7.85 |

| 6.74 | 10.46 |

| 15.01 | 8.93 |

| 13.95 | 20.09 |

| 11.16 | 17.44 |

| 25.11 | 21.80 |

5083 Aluminium Plate Weight Chart

Width: 1.000 mm | Length: 2.000 mm

| Product | Thickness | Weight |

|---|---|---|

| 5083 Aluminium Plate | 0,30 mm | 0,810 Kg/m2 |

| 5083 Aluminium Plate | 0,40 mm | 1,080 Kg/m2 |

| 5083 Aluminium Plate | 0,50 mm | 1,350 Kg/m2 |

| 5083 Aluminium Plate | 0,60 mm | 1,620 Kg/m2 |

| 5083 Aluminium Plate | 0,70 mm | 1,890 Kg/m2 |

| 5083 Aluminium Plate | 0,80 mm | 2,160 Kg/m2 |

| 5083 Aluminium Plate | 0,90 mm | 2,430 Kg/m2 |

| 5083 Aluminium Plate | 1,00 mm | 2,700 Kg/m2 |

| 5083 Aluminium Plate | 1,20 mm | 3,240 Kg/m2 |

| 5083 Aluminium Plate | 1,40 mm | 3,780 Kg/m2 |

| 5083 Aluminium Plate | 1,50 mm | 4,050 Kg/m2 |

| 5083 Aluminium Plate | 1,60 mm | 4,320 Kg/m2 |

| 5083 Aluminium Plate | 1,80 mm | 4,860 Kg/m2 |

| 5083 Aluminium Plate | 2,00 mm | 5,400 Kg/m2 |

| 5083 Aluminium Plate | 2,20 mm | 5,940 Kg/m2 |

| 5083 Aluminium Plate | 2,50 mm | 6,750 Kg/m2 |

| 5083 Aluminium Plate | 3,00 mm | 8,100 Kg/m2 |

| 5083 Aluminium Plate | 4,00 mm | 10,800 Kg/m2 |

| 5083 Aluminium Plate | 5,00 mm | 13,500 Kg/m2 |

| 5083 Aluminium Plate | 6,00 mm | 16,200 Kg/m2 |

| 5083 Aluminium Plate | 10,00 mm | 27,000 Kg/m2 |

| 5083 Aluminium Plate | 12,00 mm | 32,400 Kg/m2 |

| 5083 Aluminium Plate | 15,00 mm | 40,500 Kg/m2 |

| 5083 Aluminium Plate | 20,00 mm | 54,000 Kg/m2 |

5083 Aluminium Plate Chemical Composition

| Alloy (ISS) | Equivalent alloy (A.A) | Copper | Magnesium | Silicon | Iron | Managanese Others* (Total) | Remarks | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Old | New | U.S.A | Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | Max | Max. | Aluminum 99.0% Min. | ||

| N 8 | 54300 | 5083 | — | 0.1 | 4.0 | 4.9 | — | 0.4 | 0.7 | 0.5 | 1.0 | 0.4 | Chromium (0.15-0.35)Either Mn or Cr. shall be present. | ||

Aluminium 5083 Plate Mechanical Properties

Plate (according to the standard EN 485-2):

|

State

|

Specified thickness

|

Rm (MPa)

|

Rp0,2 (MPa)

|

A %

|

Bending radius

|

Hardness HBS

|

|||||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

More than

|

Until

|

mini

|

maxi

|

mini

|

maxi

|

A 50

|

A

|

180°

|

90°

|

||

|

F

|

>2,5

|

150,0

|

275

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

|

O/H111

|

0,20,5

1,5 3,0 6,0 12,5 50,0 80,0 120,0 |

0,51,5

3,0 6,0 12,5 50,0 80,0 120,0 150,0 |

275275

275 275 275 275 270 260 255 |

350350

350 350 350 350 345

|

125125

125 125 125 125 115 110 105 |

–

|

1112

13 15 16

|

15 14 12 12 |

1,0 e1,0 e

1,5 e

|

0,5 e1,0 e

1,0 e 1,5 e 2,5 e

|

7575

75 75 75 75 73 70 69 |

|

H112

|

>6,012,5

40,0 |

12,540,0

80,0 |

275275

270 |

–

|

125125

125 |

–

|

12

|

10

10 |

–

|

– | 7575

73 |

|

H116

|

>6,03,0

6,0 12,5 40,0 |

3,06,0

12,5 40,0 80,0 |

305305

305 305 285 |

–

|

215215

215 215 200 |

–

|

810

12

|

10 10 |

3,0 e

|

2,0 e2,5 e

4,0 e

|

8989

89 89 83 |

|

H12

|

0,20,5

1,5 3,0 6,0 12,5 |

0,51,5

3,0 6,0 12,5 40,0 |

315315

315 315 315 315 |

375375

375 375 375 375 |

250250

250 250 250 250 |

–

|

34

5 6 7

|

6 |

–

|

–

|

9494

94 94 94 94 |

|

H14

|

0,20,5

1,5 3,0 6,0 12,5 |

0,51,5

3,0 6,0 12,5 25,0 |

340340

340 340 340 340 |

400400

400 400 400 400 |

280280

280 280 280 280 |

23

3 3 4

|

3 |

–

|

–

|

–

|

102102

102 102 102 102 |

|

H16

|

0,20,5

1,5 3,0 |

0,51,5

3,0 4,0 |

360360

360 360 |

420420

420 420 |

300300

300 300 |

–

|

12

2 2 |

–

|

–

|

–

|

108108

108 108 |

|

H22/H32

|

0,20,5

1,5 3,0 6,0 12,5 |

0,51,5

3,0 6,0 12,5 40,0 |

305305

305 305 305 305 |

380380

380 380 380 380 |

215215

215 215 215 215 |

–

|

56

7 8 10

|

9 |

2,0 e2,0 e

3,0 e

|

0,5 e1,5 e

2,0 e 2,5 e 3,5 e

|

8989

89 89 89 89 |

|

H24/H34

|

0,20,5

1,5 3,0 6,0 12,5 |

0,51,5

3,0 6,0 12,5 25,0 |

340340

340 340 340 340 |

400400

400 400 400 400 |

250250

250 250 250 250 |

–

|

45

6 7 8

|

7 |

–

|

1,0 e2,0 e

2,5 e 3,5 e 4,5 e

|

9999

99 99 99 99 |

|

H26/H36

|

0,20,5

1,5 3,0 |

0,51,5

3,0 4,0 |

360360

360 360 |

420420

420 420 |

280280

280 280 |

–

|

23

3 3 |

–

|

–

|

–

|

106106

106 106 |

| Alloy Designation | UK Specifications |

US Specifications |

US Federal Specifications |

European Specifications |

Other |

|---|---|---|---|---|---|

| 5083 A95083 |

BS N8 Alloy 5083 Plate | AMS 4056 5083-0 Plate | QQ-A-200/4 5083 QQ-A-250/6 5083 Plate |

WS 3.3547 | AlMg4.5Mn A-G4.5MC |

AS/NZS 1734 Aluminium and aluminium alloys – Flat sheet, coiled sheet and plate.

| Temper | 0.2% Proof Stress, MPa min † | Tensile Strength, MPa | Elongation % min ‡ |

|---|---|---|---|

| O (annealed) | 125 – 200 | 275 – 350 | 14 |

| H112 | 125 | 275 | 10 |

| H116 | 215 | 305 | 10 |

| H321 | 215 – 295 | 305 – 385 | 10 |

† For information only, proof stress is not specified or measured except by prior agreement

‡ Minimum elongation, actual value depends on thickness – thicker gauges have higher elongation

Equivalent Specifications

USA: AA 5083; UK: BS 5083; Germany: DIN AlMg4.5Mn; Europe: EN AW-A 5083; Japan: 5083; JIS A5083P; France: NF A5083; ISO: Al Mg4.5Mn0.7.

The properties in this data sheet meet Australian/New Zealand Standard AS/NZS 1734:1997 Aluminium and aluminium alloys – Flat sheet, coiled sheet and plate (equivalent to BS EN 573-1).

Alloy 5083 can be supplied to meet other national standards.

| Temper | Tensile Strength | Yield Strength | Elongation |

|---|---|---|---|

| KSI | KSI | % | |

| O (annealed) | 42 | 21 | 14 |

| H112 | 43 | 23 | 10 |

| H116 | 46 | 33 | 10 |

| H321 | 46 | 33 | 10 |

Aluminum Alloy Heat Treatment Temper Designations

Basic Aluminum Heat Treatment Designations

- F As Fabricated

- O Annealed

- H Strain Hardened

- W Solution Heat Treated

- T Solution Heat Treated

Heat Treating T Temper Codes for Aluminium 5083 Plates

- T1 – Cooled from an elevated temperature shaping process and naturally aged to a substantially stable condition.

- T2 – Cooled from an elevated temperature shaping process, cold worked, and naturally aged to a substantially stable condition.

- T3 – Solution heat treated, cold worked, and naturally aged to a substantially stable condition.

- T4 – Solution heat treated, and naturally aged to a substantially stable condition.

- T5 – Cooled from an elevated temperature shaping process then artificially aged.

- T6 – Solution heat treated then artificially aged.

- T7 – Solution heat treated then overaged/stabilized.

- T8 – Solution heat treated, cold worked, then artificially aged.

- T9 – Solution heat treated, artificially aged, then cold worked.

- T10 – Cooled from an elevated temperature shaping process, cold worked, then artificially aged.

Additional digits may be used after the first T temper digit to indicate subsequent stress relieving by processes such as stretching, compressing, or a combination.

H Temper Strain Hardening Codes for Aluminium 5083 Plates

- H1 – Strain hardened only

- H2 – Strain hardened and partially annealed

- H3 – Strain hardened and stabilized

- H4 – Strain hardened and lacquered or painted. This assumes that thermal affects from the coating process affect the strain hardening; seldom encountered.

5083 Packing Information of Aluminum plate :

Application of 5083 Aluminium Plate

5083 Aluminium Plate is the most widely used form of Industrial Aluminium. 5083 Aluminium Plates find applications in various industries such as manufacturing cans and packages, transportation, home appliances, building and construction.