7075 Aluminium Sheet

Aluminium 7075 Sheet is an aluminum alloy, with zinc as the primary alloying element. 7075 Aluminium Sheet is strong, with a strength comparable to many steels, and has good fatigue strength and average machinability. ASTM B209 7075 Aluminium Sheet has lower resistance to corrosion than many other Al alloys, but has significantly better corrosion resistance than the 2000 alloys. Its relatively high cost limits its use to applications where cheaper alloys are not suitable. Aluminium 7075 Sheets available in many tempers, some of which are 7075-0, 7075-T6, 7075-T651.

7075 Aluminium Sheet Temper 0, H32, H34, H38 as per ASTM B209, ASTM-B-209, EN573, and EN485 international standards. Aluminum Alloy 7075 O, T6, T62, T6510, T6511, T73, T73510, or T73511, UNS A97075, AMS-QQ-A-200/11

7075-T6 Aluminum Sheet: AMS-QQ-A-250/12, AMS-4045

7075-O ALCLAD Aluminum Sheet: ASTM-B-209

7075-O BARE Aluminum Sheet: AMS-QQ-A-250/12, AMS-4045

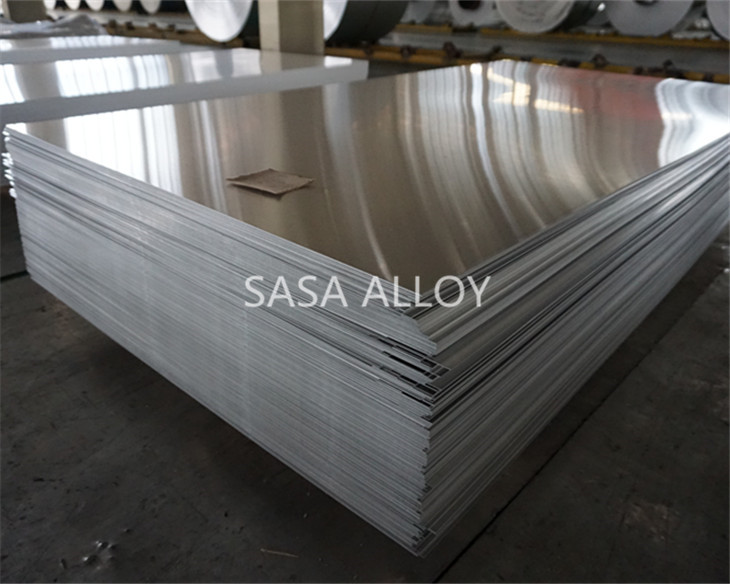

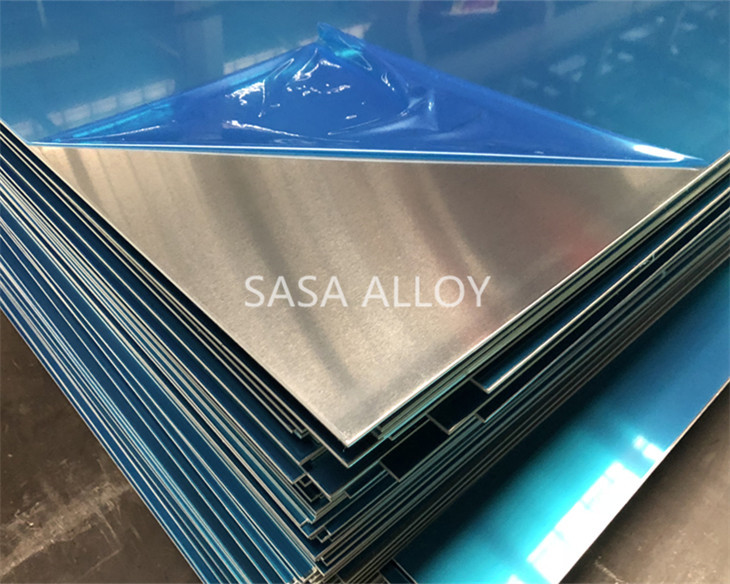

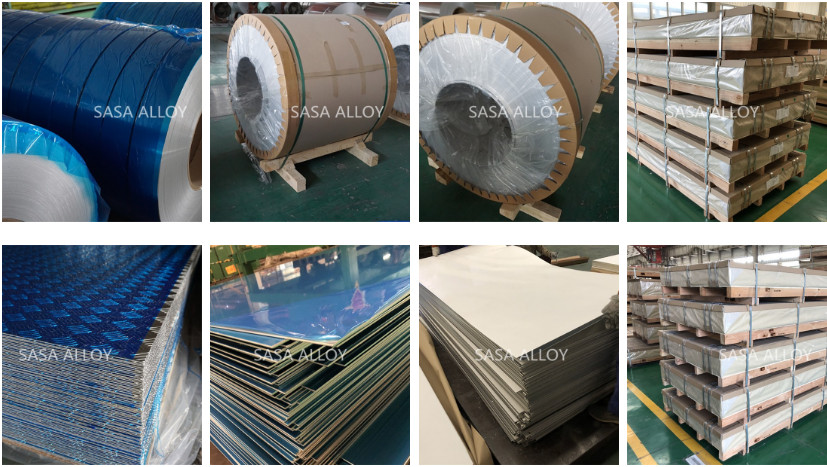

Sasa alloy is the leading manufacturer and exporter of 7075 Aluminium Sheet. Supplier of ASTM B209 7075 Aluminium Sheet from 0.5mm to 5mm Thick 1000mm x 1000mm to 2500mm x 1250mm Tempers manufactured in accordance with international standards ASTM B209, ASTM-B-209, EN573, and EN485, check 7075 Aluminium Sheet price. The general widths of 7075 H16 Aluminum sheets are 1000mm, 1250mm and 1500mm, while common lengths are 2000mm, 2500 mm and 3000mm respectively. Wholesale Trader of 7075 Commercial Aluminium Sheet offered by Sasa alloy , China. Stockist of 7075 Aluminium Sheet, H32 7075 Aluminium Stucco Sheet, H38 Commercial 7075 Aluminium Sheet, ASME SB209 7075 Aluminium Patterned Sheet, 7075 Aluminium Embossed Sheet, 7075 Aluminium Extruded Sheet, 7075 Aluminium Sheet and 7075 Aluminium Sheet in China.

Standard Dimensions of 7075 Aluminium Sheet

Standard dimensions (a x b) of Aluminium 7075 Sheet

Aluminium 7075 Sheet up to 9.9 mm

2.000 x 1.000 mm

2.500 x 1.250 mm

3.000 x 1.500 mm

Oversize Aluminium 7075 Sheet

4.000 x 2.000 mm

6.000 x 2.500 mm

8.000 x 2.500 mm

Other dimensions on request

| Alloy | ASTM B209 1050, 1060, 1100, 1235, 3003, 3004, 3105, 5052, 5754, 6061, 8011 |

| Aluminium 7075 Sheet Temper | O, H12, H14, H16, H18, H22, H24, H26, H32, H112 |

| Aluminium 7075 Sheet Thickness | 0.5mm-150mm |

| Aluminium 7075 Sheet Width | 500-2000mm |

| Aluminium 7075 Sheet Length | to clients’ requirement |

| Aluminium 7075 Sheet Coating | Polyester, Fluorocarbon, polyurethane and epoxy coating |

| 7075 Aluminium Sheet Coating finish | PVDF, POLYESTER(PE) |

| Surface | Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc. |

| Gloss | Meet the customer requirement |

| Total coating thickness | PVDF coating: More than 25 micron; Polyester coating: More than 18 micron |

| Coating hardness | (pencil hardness) more than 2H |

| Coating adhesive | No lower than1st grade |

| Impact resistance | No cracking or peeling (50kg/cm, ASTMD-2794: 1993) |

| Flexibility (T-bend) | 2T |

| MEK resistance | More than 10 |

| Available Aluminium 7075 Sheet Stock Sizes | 1ft x 1ft, 1ft x 2ft, 1ft x 4ft, 2ft x 2ft, 2ft x 4ft, 4ft x 4ft, 4ft x 8ft, 4ft x 10ft or Cut to Size or Custom Shape. |

| Aluminium 7075 Sheet Delivery Time | 30-60 days after receiving the prepayment |

| Aluminium 7075 Alclad Sheet Packaging Details | Standard export package. One pallet is about 2-3 ton.Two steel belts in width and three in width. One 20GP container can load about 18-20 tons Aluminium 7075 Sheet. One 40GP container can load about 24 tons Aluminium 7075 Sheet |

| ASTM B209 Alloy 7075 Outer packing | Export standard, wooden pallet |

| Bottom side Aluminium 7075 Sheet is coated with protective polyester material, thickness more than 6 micron | |

| Export to | Singapore, Indonesia, Ukraine, Korea, Thailand, Vietnam, Saudi Arabia, Brazil, Spain, Canada, USA, Egypt, Iran, China, Kuwait, Dubai, Oman, Kuwait, Peru, Mexico, Iraq, Russia, Malaysia, etc. |

7075 Aluminium Sheet Products Show:

| 7075 Aluminium Sheets Product Range | ||||

|---|---|---|---|---|

| Alloy No. | Thickness (mm) |

Width (mm) |

Length (mm) |

Temper |

| A1050, A1060, A1070, A1100 | 0.2-5.0 | 20-2200 | 20-8000 | O, H12, H22, H14, H16, H18, H24, H26 |

| A3003, A3105, A3004 | 0.2-5.0 | 20-2200 | 20-8000 | O, H14, H18, H24 |

| A5052, A5005, A5083, A5086, A5754 | 0.2-5.0 | 20-2200 | 20-8000 | O, H18, H24, H32, H34, H111, H112 |

| A6061, A6082, A6063 | 0.2-5.0 | 20-2200 | 20-8000 | T4, T6, T651 |

| A8011 | 0.2-5.0 | 20-2200 | 20-8000 | O, H12, H22, H14, H16, H18, H24, H26 |

Aluminium 7075 Sheets Manufacturer in China:

1100-H14 Aluminum Sheet: ASTM-B-209

2024-T3 ALCLAD Aluminum Sheet: AMS-QQ-A-205/5, ASTM-B-209, AMS-4041

2024-T3 BARE Aluminum Sheet: AMS-QQ-A-205/5, ASTM-B-209, AMS-4037

2219-T6 Aluminum Sheet:

2219-O Aluminum Sheet: AMS-QQ-A-250/30

3003-H14 Aluminum Sheet: ASTM-B-209

3003-O Aluminum Sheet: ASTM-B-209

4047-F Aluminum Sheet: AMS-4185, BAlSi-4

5052-H32 Aluminum Sheet: ASTM-B-209, AMS-4016

5052-H38 Aluminum Sheet: ASTM-B-209

5052-O Aluminum Sheet: ASTM-B-209, AMS-4015

6061-O Aluminum Sheet: ASTM-B-209, AMS-4025

6061-T4 Aluminum Sheet: ASTM-B-209, AMS-4026

6061-T6 Aluminum Sheet: ASTM-B-209, AMS 4027

7075-T6 Aluminum Sheet: AMS-QQ-A-250/12, AMS-4045

7075-O ALCLAD Aluminum Sheet: ASTM-B-209

7075-O BARE Aluminum Sheet: AMS-QQ-A-250/12, AMS-4045

Aluminum Specular Lighting Sheet

| ALLOYS | SPECIFICATIONS |

|---|---|

| 1100 | AMS-4001, 4003, QQ-A-250/1 |

| 2014-BARE | AMS-4028, 4029 |

| 2014-ALCLAD | QQ-A-250/3 |

| 2024-BARE | AMS-4035,37, QQ-A-250/4 |

| 2024-ALCLAD | AMS-4040, 41, QQ-A-250/5 |

| 2124 | AMS-4101, QQ-A-250/29 |

| 2219 | AMS-4031, 94, 95, QQ-A-250/30 |

| 3003 | AMS-4006, 4008, QQ-A-250/2 |

| 5052 | AMS-4015, 16, 17, QQ-A-250/8 |

| 6013 | AMS-4347, 4216 |

| 6061 | AMS-4025, 26, 27, QQ-A-250/11 |

| 7050 | AMS-4050, 4201, BMS-7-194 |

| 7075-BARE | AMS-4044, 45, QQ-A-250/12 |

| 7075-ALCLAD | AMS-4048, 49, QQ-A-250/13 |

| 7178-BARE | QQ-A-250/14 |

| 7178-ALCLAD | QQ-A-250/15 |

| 7475 | AMS-4084, 4085 |

| Sizes: | .008 to .249 x R/W x R/L .250 to 18.00 x R/W x R/L |

Please note: Other alloys available upon request

* Special Tolerances Available

* Polishing & PVC Protected

Standard Specification of 7075 Aluminium Sheet

Standards and specifications by country

| Specification | Alloy | Temper | Company |

|---|---|---|---|

| Europe | |||

| EN 2089/2395 | 2014A | T6(T62)/T4(T42) | |

| EN 2087/2088 | 2014A clad | T6(T62)/T4(T42) | |

| EN 4101 | 2024 | T4 | |

| EN 2090/2091/2703/4001 | 2024 clad cmq | T3/T4/T4(T42)/T351 | |

| EN 3474/3997/3998/3999 | 2024 cmq | T81/T3/T4(T42)/T351 | |

| EN 2694/EN 3341 | 6061 | T6(T62)/T4(T42) | |

| EN 4449/4450 | 7050 | T76/F(T762) | |

| EN 2696 | 7075 | T6(T62) | |

| EN 2092 | 7075 clad | T6(T62) | |

| EN 2802/3333 | 7475 | T761/F(T762) | |

| EN 2803/3332 | 7475 clad | T761/F(T762) | |

| France | |||

| AIR 9048.010/.030/ | 2014 | F(T42)/F(T62)/T4/ | |

| .020/.040/.050 | 2014 | T6/T451 | |

| AIR 9048.060/.080/.070/.090 | 2014 clad | F(T42)/F(T62)/T4/T6 | |

| AIR 9048.100/.110/.120 | 2024 | ||

| AIR 9048.130/.140 | 2024 clad | F(T42)/T3 | |

| AIR 9048.150 | 2618A | H28(T62) | |

| AIR 9048.170 | 2618A clad | H28(T62) | |

| AIR 9048.190/.200 | 5086 | O, H111/H22, H32 | |

| AIR 9048.210/.220/.230/.240 | 6061 | O, H111(T42)/T4/ O, H111(T62)/T6 | |

| AIR 9048.260/.270 | 7075 | T6/T76 | |

| AIR 9048.280 | 7075 clad | T6 | |

| AIR 9048.290 | 7475 | T76 | Boeing |

| Germany | |||

| W.-Nr. 3.1254 | 2014A | T4, T6 | |

| W.-Nr. 3.1354 | 2024 | O(T42), T3 | |

| W.-Nr. 3.1364 | 2024 clad | O(T42), T3 | |

| W.-Nr. 3.3214 | 6061 | O(T62), T6 | |

| W.-Nr. 3.4364 | 7075 | T6 | |

| W.-Nr. 3.4374 | 7075 clad | O(T62), T6 | |

| W.-Nr. 3.4377 | 7475 clad | T76 | |

| UK | |||

| BS L16/17 | 1200 | H4/O | |

| BS L156/157/158*/159* | 2014A | ||

| 158*/159* | 2014A clad | (T42)(T62) | BAE Systems |

| BS L163/164/165 | 2014A clad | T3/F(T42), T4/T6 | |

| BS L166*/167* | 2014A clad | F(T42), T4/T6 | |

| BS L109/110 | 2024 clad | T3/F(T42) | |

| DTD5070 | 2618A clad | T6 | |

| BS L59/60/61 | 3103 | H6/H2/O | |

| BS L80/81 | 5251 | O/H6 | |

| BS L113 | 6082 | T4, T6 | |

| BS L88 | 7075 clad | T6 | |

| USA | |||

| AMS QQ-A-250/3 | 2014 clad | O, T4, T6 | |

| AMS QQ-A-250/4 | 2024 | O, T3 | |

| AMS 4037 | 2024 | T3 | |

| AMS QQ-A-250/5 | 2024 clad | O, T3 | |

| AMS 4041 | 2024 clad | T3 | |

| AMS QQ-A-250/30 | 2219 | O(T62), T31(T81), T37(T87) | |

| AMS QQ-A-250/2 | 3003 | O, H14 | |

| AMS 4347 | 6013 | T4 | |

| AMS 4216 | 6013 | T6 | |

| AMS 4025/4026/4027 | 6061 | O, F, T4, T42, T45, T6, T62, T651 | |

| AMS QQ-A-250/12 | 7075 | O, T6, T73 | |

| AMS QQ-A-250/24 | 7075 | T76 | |

| AMS QQ-A-250/13 | 7075 clad | O, T6, T73 | |

| AMS QQ-A-250/26 | 7075 clad with 7011 | T76 | |

| AMS QQ-A-250/25 | 7075 clad with 7072 | T76 | |

| European Standard | BS (OLD) | USA (AA) | GERMANY (DIN) | ISO | IS | Canadian |

|---|---|---|---|---|---|---|

| EN AW-1050 A | 1E | 1050 | Al99.5 | Al99.5 | 19500, 19501 | 1 S |

| EN AW-1070 A | – | 1070 | Al-99.7 | Al-99.7 | 19700 | – |

| EN AW-1100 | IC | 1100 | Al-99.0 | Al-99.0 | 19000 | 2 S |

| EN AW-2011 | FC1 | 2011 | AlCuBiPb | AlCu6BiPb | – | 28S |

| EN AW-2014 | HE15 | 2014 | AlCuSiMn | AlCu4SiMg | 24345 | B26S |

| EN AW-2024 | – | 2024 | AlCuMg2 | AlCu4Mg1 | – | 24 S |

| EN AW-3003 | N3 | 3003 | AlMnCu | AlMn1Cu | 31000 | 3 S |

| EN AW-3103 | – | 3103 | – | AlMn1 | – | – |

| EN AW-6101A | E91E | 6101 | E AlMgSi 0.5 | E AlMgSi(A) | 63401 | D50S |

| EN AW-6005 | – | 6005 | AlMgSi0.7 | AlSiMg | 62400 | C51S |

| EN AW-6351 | HE30 | 6351 | AlMgSi1 | AlSiMg0.5Mn | 64430 | B51S |

| EN AW-6060 | – | 6060 | AlMgSi 0.5 | AlMgSi | – | – |

| EN AW-6061 | HE20 | 6061 | AlMgSiCu | AlMg1SiCu | 65032 | 65S |

| EN AW-6063 | HE9 | 6063 | AlMgSi0.5 | AlMg0.7Si | 63400 | 50S |

| EN AW-6082 | HE30 | 6351 | AlMgSi1 | AlSi1MgMn | 64430 | B51S |

7075 Aluminium Sheet Sizes

| Sizes (mm) | Theoretical Mass KG/sheet |

|---|---|

| 2000 X 1000 X 0.5 | 2500 X 1250 X 0.5 |

| 2000 X 1000 X 0.7 | 2500 X 1250 X 0.7 |

| 2000 X 1000 X 0.9 | 2500 X 1250 X 0.9 |

| 2000 X 1000 X 1.2 | 2500 X 1250 X 1.2 |

| 3000 X 1500 X 1.2 | 2000 X 1000 X 1.6 |

| 2500 X 1250 X 1.6 | 3000 X 1500 X 1.6 |

| 2000 X 1000 X 2.0 | 2500 X 1250 X 2.0 |

| 3000 X 1500 X 2.0 | 2500 X 1250 X 2.5 |

| 2.79 | 4.36 |

| 3.91 | 6.10 |

| 5.02 | 7.85 |

| 6.74 | 10.46 |

| 15.01 | 8.93 |

| 13.95 | 20.09 |

| 11.16 | 17.44 |

| 25.11 | 21.80 |

7075 Aluminium Sheet Weight Chart

Width: 1.000 mm | Length: 2.000 mm

| Product | Thickness | Weight |

|---|---|---|

| 7075 Aluminium Sheet | 0,30 mm | 0,810 Kg/m2 |

| 7075 Aluminium Sheet | 0,40 mm | 1,080 Kg/m2 |

| 7075 Aluminium Sheet | 0,50 mm | 1,350 Kg/m2 |

| 7075 Aluminium Sheet | 0,60 mm | 1,620 Kg/m2 |

| 7075 Aluminium Sheet | 0,70 mm | 1,890 Kg/m2 |

| 7075 Aluminium Sheet | 0,80 mm | 2,160 Kg/m2 |

| 7075 Aluminium Sheet | 0,90 mm | 2,430 Kg/m2 |

| 7075 Aluminium Sheet | 1,00 mm | 2,700 Kg/m2 |

| 7075 Aluminium Sheet | 1,20 mm | 3,240 Kg/m2 |

| 7075 Aluminium Sheet | 1,40 mm | 3,780 Kg/m2 |

| 7075 Aluminium Sheet | 1,50 mm | 4,050 Kg/m2 |

| 7075 Aluminium Sheet | 1,60 mm | 4,320 Kg/m2 |

| 7075 Aluminium Sheet | 1,80 mm | 4,860 Kg/m2 |

| 7075 Aluminium Sheet | 2,00 mm | 5,400 Kg/m2 |

| 7075 Aluminium Sheet | 2,20 mm | 5,940 Kg/m2 |

| 7075 Aluminium Sheet | 2,50 mm | 6,750 Kg/m2 |

| 7075 Aluminium Sheet | 3,00 mm | 8,100 Kg/m2 |

| 7075 Aluminium Sheet | 4,00 mm | 10,800 Kg/m2 |

| 7075 Aluminium Sheet | 5,00 mm | 13,500 Kg/m2 |

| 7075 Aluminium Sheet | 6,00 mm | 16,200 Kg/m2 |

| 7075 Aluminium Sheet | 10,00 mm | 27,000 Kg/m2 |

| 7075 Aluminium Sheet | 12,00 mm | 32,400 Kg/m2 |

| 7075 Aluminium Sheet | 15,00 mm | 40,500 Kg/m2 |

| 7075 Aluminium Sheet | 20,00 mm | 54,000 Kg/m2 |

7075 Aluminium Sheet Chemical Composition

| Alloy (ISS) | Equivalent alloy (A.A) | Copper | Magnesium | Silicon | Iron | Managanese Others* (Total) | Remarks | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Old | New | U.S.A | Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | Max | Max. | Aluminum 99.0% Min. | ||

| — | — | 7075 | 1.20 | 2.0 | 2.1 | 2.9 | — | 0.5 | 0.7 | — | 0.3 | 0.2 | Zinc (5.1-6.1) & Chromium (0.2-0.28) | ||

Aluminium 7075 Sheet Mechanical Properties

| Mechanical Properties of Aluminium 7075-T6 Sheet | |||

| Hardness, Brinell | 150 | 150 | AA; Typical; 500 g load; 10 mm ball |

| Hardness, Knoop | 191 | 191 | Converted from Brinell Hardness Value |

| Hardness, Rockwell A | 53.5 | 53.5 | Converted from Brinell Hardness Value |

| Hardness, Rockwell B | 87 | 87 | Converted from Brinell Hardness Value |

| Hardness, Vickers | 175 | 175 | Converted from Brinell Hardness Value |

| Ultimate Tensile Strength | 572 MPa | 83000 psi | AA; Typical |

| Tensile Yield Strength | 503 MPa | 73000 psi | AA; Typical |

| Elongation at Break | 11 % | 11 % | AA; Typical; 1/16 in. (1.6 mm) Thickness |

| Elongation at Break | 11 % | 11 % | AA; Typical; 1/2 in. (12.7 mm) Diameter |

| Modulus of Elasticity | 71.7 GPa | 10400 ksi | AA; Typical; Average of tension and compression. Compression modulus is about 2% greater than tensile modulus. |

| Poisson’s Ratio | 0.33 | 0.33 | |

| Fatigue Strength | 159 MPa | 23000 psi | AA; 500,000,000 cycles completely reversed stress; RR Moore machine/specimen |

| Fracture Toughness | 20 MPa-m½ | 18.2 ksi-in½ | K(IC) in S-L Direction |

| Fracture Toughness | 25 MPa-m½ | 22.8 ksi-in½ | K(IC) in T-L Direction |

| Fracture Toughness | 29 MPa-m½ | 26.4 ksi-in½ | K(IC) in L-T Direction |

| Machinability | 70 % | 70 % | 0-100 Scale of Aluminum Alloys |

| Shear Modulus | 26.9 GPa | 3900 ksi | |

| Shear Strength | 331 MPa | 48000 psi | AA; Typical |

| Alloy Designation | UK Specifications |

US Specifications |

US Federal Specifications |

European Specifications |

Other |

|---|---|---|---|---|---|

| 7075 A97075 A87075 |

BS 2 L95 Alloy 7075-T651 Plate BS 2 L88 Alloy 7075-T6 Clad Sheet and Strip BS L160 Alloy 7075-T73511 Bars and Sections BS L161 Alloy 7075 Forging Stock and Forgings BS L162 Alloy 7075 Forging Stock and Forgings BS L170 Alloy 7075-T6511 Bars and Sections DTD 5110 7075 Clad Plate DTD 5124 7075 Bars and Sections |

AMS 4038 7075-T651 Superseded by AMS 4045 AMS 4039 7075-T651 Superseded by AMS 4049 AMS 4044 7075 -0 Sheet and Plate AMS 4045 7075-T6 Sheet and T651 Plate AMS 4046 7075-T6 Alclad one side Sheet, T651 Plate AMS 4048 7075-T0 Alclad Sheet and Plate AMS 4049 7075 -T6 Alclad Sheet and T651 Plate AMS 4078 7075-T351 Plate AMS 4122 7075-T6 Cold finished rod, bar, wire AMS 4123 7075-T651 Cold finished bar, rod AMS 4124 7075-T7351 Cold finished bar, rod, wire AMS 4126 7075-T6 Forgings AMS 4131 7075-T74 Forgings AMS 4139 7075 Forgings (Non-Current) AMS 4141 7075-T73 Die Forgings AMS 4147 7075-T7352 Forgings AMS 4154 7075-T6 Extrusions AMS 4166 7075-T73 Extrusion AMS 4167 7075-T73511 Extrusions AMS 4168 7075-T6511 Extrusions Unstraightened AMS 4169 7075-T6511 Extrusions Straightened AMS 4174 7075-T73 Flash Welded Rings AMS 4186 7075-TF Cold finished bar, rod, wire AMS 4187 7075-0 Cold finished bar, rod, wire |

QQ-A-250/13 7075-0 Alclad sheet and plate QQ-A-250/13 7075-T6 Alclad sheet and plate QQ-A-250/18 7075-0 Clad one side, sheet and plate QQ-A-250/18 7075-T6 Clad one side, sheet and plate QQ-A-250/24 7075-T7651 Plate QQ-A-250/25 7075 Sheet, clad with7072-T76 QQ-A-250/26 7075 Sheet, clad with7011-T76 QQ-A-367 Alloy 7075-T6 Forgings MIL-A-22771 |

EN 2127 | AIR 9048.690 7075-T7351 Plate AIR 9048.700 7075-T7351 Plate AIR 9048.710 7075-T7351 Plate AIR 9049 |

Key Words: Aluminium 7075-T6; Aluminium 7075-T651, UNS A97075; ISO AlZn5.5MgCu; Aluminium 7075-T6; Aluminium 7075-T651; AA7075-T6

Aluminum Alloy Heat Treatment Temper Designations

Basic Aluminum Heat Treatment Designations

- F As Fabricated

- O Annealed

- H Strain Hardened

- W Solution Heat Treated

- T Solution Heat Treated

Heat Treating T Temper Codes

- T1 – Cooled from an elevated temperature shaping process and naturally aged to a substantially stable condition.

- T2 – Cooled from an elevated temperature shaping process, cold worked, and naturally aged to a substantially stable condition.

- T3 – Solution heat treated, cold worked, and naturally aged to a substantially stable condition.

- T4 – Solution heat treated, and naturally aged to a substantially stable condition.

- T5 – Cooled from an elevated temperature shaping process then artificially aged.

- T6 – Solution heat treated then artificially aged.

- T7 – Solution heat treated then overaged/stabilized.

- T8 – Solution heat treated, cold worked, then artificially aged.

- T9 – Solution heat treated, artificially aged, then cold worked.

- T10 – Cooled from an elevated temperature shaping process, cold worked, then artificially aged.

Additional digits may be used after the first T temper digit to indicate subsequent stress relieving by processes such as stretching, compressing, or a combination.

H Temper Strain Hardening Codes

- H1 – Strain hardened only

- H2 – Strain hardened and partially annealed

- H3 – Strain hardened and stabilized

- H4 – Strain hardened and lacquered or painted. This assumes that thermal affects from the coating process affect the strain hardening; seldom encountered.

7075 Packing Information of Aluminum plate :

Application of 7075 Aluminium Sheet

7075 Aluminium Sheet is the most widely used form of Industrial Aluminium. 7075 Aluminium Sheets find applications in various industries such as manufacturing cans and packages, transportation, home appliances, building and construction.

7075 Aluminium Sheet Applications