Inconel 690 is a high-performance nickel-based alloy that exhibits excellent corrosion resistance in harsh environments, high strength, and excellent mechanical properties at both high and low temperatures. Inconel 690 flanges are commonly used in high-temperature and high-pressure applications, such as in the chemical and petrochemical industries, aerospace and defense, and marine applications.

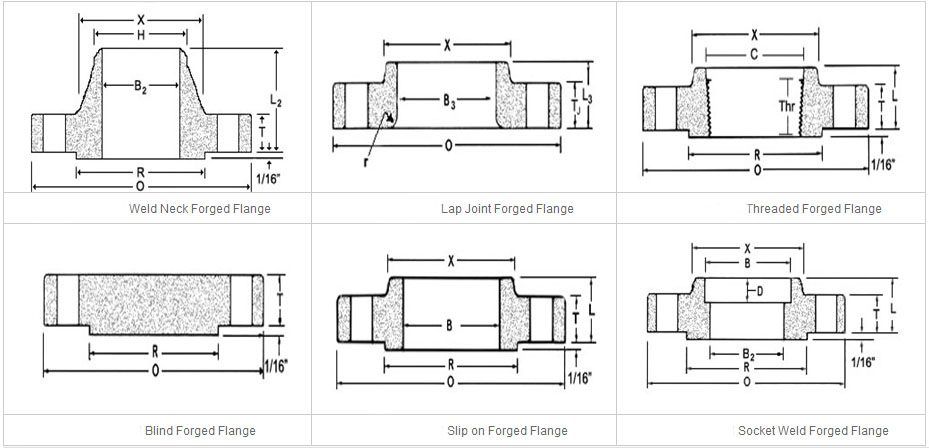

Inconel 690 flanges come in different types and dimensions, including weld-neck flanges, slip-on flanges, socket-weld flanges, blind flanges, and lap joint flanges. These flanges are available in various sizes and pressure ratings, ranging from ½” to 48″ and class 150 to class 2500.

Inconel 690 flanges are designed to withstand high temperatures and pressure, making them suitable for use in critical applications. These flanges are also resistant to pitting, crevice corrosion, and intergranular attack, making them ideal for use in harsh environments.

| Specifications of Inconel 690 Flanges: |

| Grade |

Inconel Alloy 690 / UNS N06690 |

| Standard |

ASTM B564, ASME SB564 |

| Dimensions |

ANSI / ASME B16.5, B16.47 Series A & B, B.16.48, BS4504, BS10, DIN, EN-1092, MSS SP44 |

| Size |

1/2″ – 48″ (15NB – 1200NB) |

| Class / Pressure Rating |

150 Class, 300 Class, 600 Class, 900 Class, 1500 Class, 2500 Class, PN6, PN10, PN16, PN25, PN40, PN64, etc. |

| Form |

Slip on Flanges (SORF), Threaded Flanges, Weld neck Flanges (WNRF), Blind Flanges, Socket weld Flanges, Lap Joint Flanges, Ring Type Joint Flanges, Spectacle Blind Flanges, Spacer Ring Flanges, Long weld Neck Flanges, Nipo Flange, Nipolet Flanges, Plate Flanges, Flat Flange, Orifice Flanges, Forged Flanges |

| Flange Face Type |

Flat Face (FF), Raised Face (RF), Ring Type Joint(RTJ) |

| TYPE OF Inconel 690 Flanges: |

- •Alloy 690 WNRF Flanges

- •UNS N06690 WNRF Flanges

- •ASTM B564 Inconel 690 WNRF Flanges

- •ASME B16.5 Alloy 690 WNRF Flanges

|

- •Alloy 690 BLRF Flanges

- •UNS N06690 BLRF Flanges

- •ASTM B564 Inconel 690 BLRF Flanges

- •ASME B16.5 Alloy 690 BLRF Flanges

|

- •Alloy 690 SWRF Flanges

- •UNS N06690 SWRF Flanges

- •ASTM B564 Inconel 690 SWRF Flanges

- •ASME B16.5 Alloy 690 SWRF Flanges

|

- •Alloy 690 SORF Flanges

- •UNS N06690 SORF Flanges

- •ASTM B564 Inconel 690SORF Flanges

- •ASME B16.5 Alloy 690 SORF Flanges

|

- •Alloy 690 Reducing Flanges

- •UNS N06690 Reducing Flanges

- •ASTM B564 Inconel 690 Reducing Flanges

- •ASME B16.5 Alloy 690 Reducing Flanges

|

- •Alloy 690 Flat Flanges

- •UNS N06690 Flat Flanges

- •ASTM B564 Inconel 690 Flat Flanges

- •ASME B16.5 Alloy 690 Flat Flanges

|

| DIMENSIONS OF Inconel 690 Flanges: |

| AVAILABLE STOCK OF Inconel 660 Flanges: |

| Preview |

Products |

UNS |

DIN |

|

Inconel 690 WNRF Flange |

UNS N06690 WNRF Flange |

2.4816 WNRF Flange |

|

Inconel 690 SWRF Flange |

UNS N06690 SWRF Flange |

2.4816 SWRF Flange |

|

Inconel 690 BLRF Flange |

UNS N06690 BLRF Flange |

2.4816 BLRF Flange |

|

Inconel 690 BLRF Flange |

UNS N06690 BLRF Flange |

2.4816 BLRF Flange |

|

Inconel 690 SORF Flange |

UNS N06690 SORF Flange |

2.4816SORF Flange |

|

Inconel 690 RTJ Flange |

UNS N06690 RTJ Flange |

2.4816RTJ Flange |

| EQUIVALENT GRADES OF Inconel 690Flanges : |

| STANDARD |

WERKSTOFF NR. |

UNS |

GOST |

AFNOR |

JIS |

BS |

EN |

| Inconel 690 |

2.4816 |

N06690 |

НП-2 |

- |

NW 6690 |

NA 12 |

NLC-Ni 99 |

| MECHANICAL PROPERTIES OF Inconel Alloy 690 Flanges : |

| Density |

Melting Point |

Tensile Strength |

Yield Strength (0.2%Offset) |

Elongation |

| 8.9 g/cm3 |

1446 °C (2635 °F) |

Psi – 67000 , MPa – 462 |

Psi – 21500 , MPa – 148 |

45 % |

| Inconel Alloy 690 Flanges: |

| Grade |

Ni |

Fe |

C |

Mn |

Si |

Cu |

Mg |

Ti |

S |

| Inconel 690 |

99.0 min |

0.4 max |

0.15 max |

0.35 max |

0.1 max |

0.25 max |

- |

- |

0.01 max |

1. You can get the perfect material according to your requirement at the least possible price.

2. We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. We guarantee to give a response within 24hours(usually in the same hour)

5. You can get stock alternatives, mill deliveries with minimizing manufacturing time.

6. We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Sasa alloy’s pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,

Previous: Inconel X750 Flanges

Next: Incoloy A286 Fitting