LM-2 Aluminium Sheet

EN AC 46100 Sheet is an aluminum alloy formulated for casting. Aluminium LM2 Sheet is typically furnished in the as-fabricated (no temper or treatment) condition. EN 1706 Aluminium Sheet is a little difficult to machine since the high silicon content causes rapid tool wear. It is, however, far easier than the LM6 and LM20 alloys as the tendency to drag is practically eliminated by the presence of copper and other elements. Resistance to corrosion by ordinary atmospheric conditions is good and by marine atmosphere fairly good. ASTM B209 LM2 Aluminium Sheet is inferior in this respect to LM6 but can be improved by anodic treatment.

LM2 Sheet can be anodically treated to give a protective surface of a darkish grey colour The surfaces of die-castings. however, are not generally suitable for decorative anodising. This alloy conforms to BS 1490:1988 LM2.

LM-2 Aluminium Sheet Temper 0, H32, H34, H38 as per ASTM B209, ASTM-B-209, EN573, and EN485 international standards. Aluminium Casting Alloy (AL – Si10Cu2Fe), EN 1706 AC-46100, LM2 (EN 1706 AC-46100) – Aluminium Casting Alloy

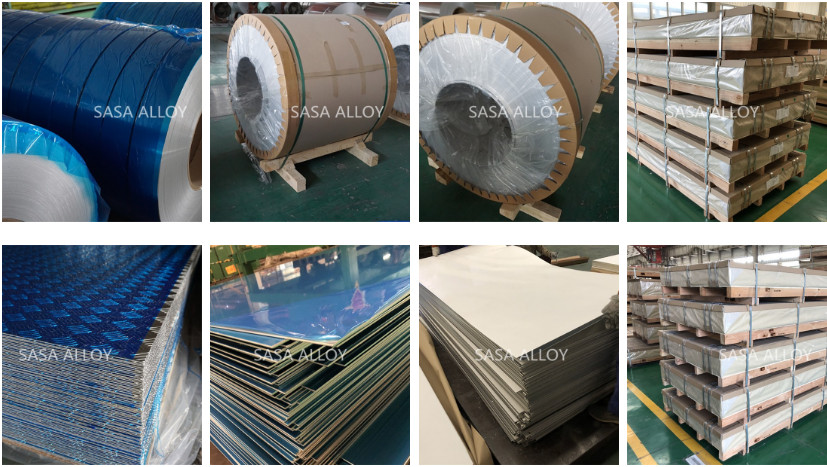

Sasa alloy is the leading manufacturer and exporter of LM-2 Aluminium Sheet. Supplier of ASTM B209 LM-2 Aluminium Sheet from 0.5mm to 5mm Thick 1000mm x 1000mm to 2500mm x 1250mm Tempers manufactured in accordance with international standards ASTM B209, ASTM-B-209, EN573, and EN485, check LM-2 Aluminium Sheet price. The general widths of LM-2 H16 Aluminum sheets are 1000mm, 1250mm and 1500mm, while common lengths are 2000mm, 2500 mm and 3000mm respectively. Wholesale Trader of LM-2 Commercial Aluminium Sheet offered by Sasa alloy , China. Stockist of LM-2 Aluminium Sheet, H32 LM-2 Aluminium Stucco Sheet, H38 Commercial LM-2 Aluminium Sheet, ASME SB209 LM-2 Aluminium Patterned Sheet, LM-2 Aluminium Embossed Sheet, LM-2 Aluminium Extruded Sheet, LM-2 Aluminium Sheet and LM-2 Aluminium Sheet in China.

Standard Dimensions of LM-2 Aluminium Sheet

Standard dimensions (a x b) of Aluminium LM-2 Sheet

Aluminium LM-2 Sheet up to 9.9 mm

2.000 x 1.000 mm

2.500 x 1.250 mm

3.000 x 1.500 mm

Oversize Aluminium LM-2 Sheet

4.000 x 2.000 mm

6.000 x 2.500 mm

8.000 x 2.500 mm

Other dimensions on request

| Alloy | ASTM B209 1050, 1060, 1100, 1235, 3003, 3004, 3105, 5052, 5754, 6061, 8011 |

| Aluminium LM-2 Sheet Temper | O, H12, H14, H16, H18, H22, H24, H26, H32, H112 |

| Aluminium LM-2 Sheet Thickness | 0.5mm-150mm |

| Aluminium LM-2 Sheet Width | 500-2000mm |

| Aluminium LM-2 Sheet Length | to clients’ requirement |

| Aluminium LM-2 Sheet Coating | Polyester, Fluorocarbon, polyurethane and epoxy coating |

| LM-2 Aluminium Sheet Coating finish | PVDF, POLYESTER(PE) |

| Surface | Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc. |

| Gloss | Meet the customer requirement |

| Total coating thickness | PVDF coating: More than 25 micron; Polyester coating: More than 18 micron |

| Coating hardness | (pencil hardness) more than 2H |

| Coating adhesive | No lower than1st grade |

| Impact resistance | No cracking or peeling (50kg/cm, ASTMD-2794: 1993) |

| Flexibility (T-bend) | 2T |

| MEK resistance | More than 10 |

| Available Aluminium LM-2 Sheet Stock Sizes | 1ft x 1ft, 1ft x 2ft, 1ft x 4ft, 2ft x 2ft, 2ft x 4ft, 4ft x 4ft, 4ft x 8ft, 4ft x 10ft or Cut to Size or Custom Shape. |

| Aluminium LM-2 Sheet Delivery Time | 30-60 days after receiving the prepayment |

| Aluminium LM-2 Alclad Sheet Packaging Details | Standard export package. One pallet is about 2-3 ton.Two steel belts in width and three in width. One 20GP container can load about 18-20 tons Aluminium LM-2 Sheet. One 40GP container can load about 24 tons Aluminium LM-2 Sheet |

| ASTM B209 Alloy LM-2 Outer packing | Export standard, wooden pallet |

| Bottom side Aluminium LM-2 Sheet is coated with protective polyester material, thickness more than 6 micron | |

| Export to | Singapore, Indonesia, Ukraine, Korea, Thailand, Vietnam, Saudi Arabia, Brazil, Spain, Canada, USA, Egypt, Iran, China, Kuwait, Dubai, Oman, Kuwait, Peru, Mexico, Iraq, Russia, Malaysia, etc. |

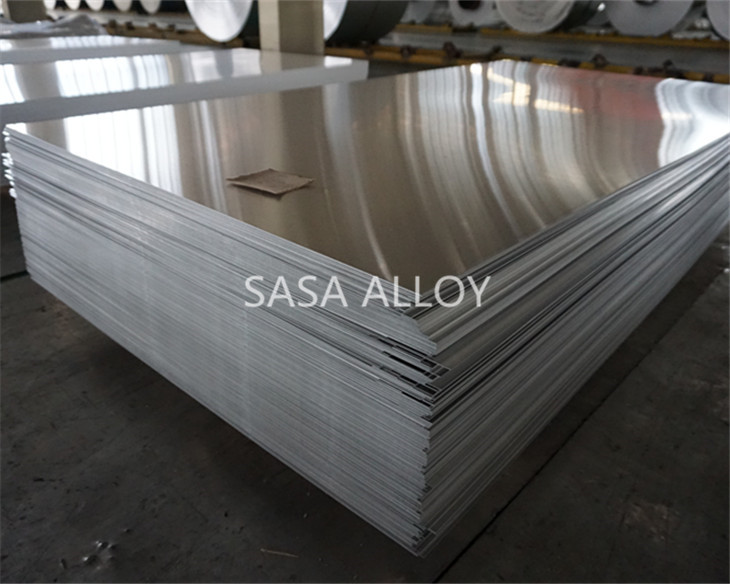

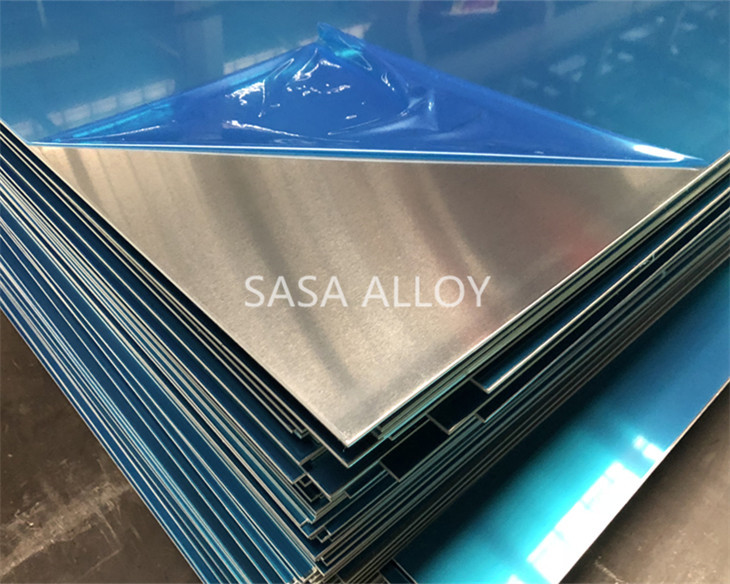

LM-2 Aluminium Sheet Products Show:

| LM-2 Aluminium Sheets Product Range | ||||

|---|---|---|---|---|

| Alloy No. | Thickness (mm) |

Width (mm) |

Length (mm) |

Temper |

| A1050, A1060, A1070, A1100 | 0.2-5.0 | 20-2200 | 20-8000 | O, H12, H22, H14, H16, H18, H24, H26 |

| A3003, A3105, A3004 | 0.2-5.0 | 20-2200 | 20-8000 | O, H14, H18, H24 |

| A5052, A5005, A5083, A5086, A5754 | 0.2-5.0 | 20-2200 | 20-8000 | O, H18, H24, H32, H34, H111, H112 |

| A6061, A6082, A6063 | 0.2-5.0 | 20-2200 | 20-8000 | T4, T6, T651 |

| A8011 | 0.2-5.0 | 20-2200 | 20-8000 | O, H12, H22, H14, H16, H18, H24, H26 |

Aluminium LM-2 Sheets Manufacturer in China:

1100-H14 Aluminum Sheet: ASTM-B-209

2024-T3 ALCLAD Aluminum Sheet: AMS-QQ-A-205/5, ASTM-B-209, AMS-4041

2024-T3 BARE Aluminum Sheet: AMS-QQ-A-205/5, ASTM-B-209, AMS-4037

2219-T6 Aluminum Sheet:

2219-O Aluminum Sheet: AMS-QQ-A-250/30

3003-H14 Aluminum Sheet: ASTM-B-209

3003-O Aluminum Sheet: ASTM-B-209

4047-F Aluminum Sheet: AMS-4185, BAlSi-4

5052-H32 Aluminum Sheet: ASTM-B-209, AMS-4016

5052-H38 Aluminum Sheet: ASTM-B-209

5052-O Aluminum Sheet: ASTM-B-209, AMS-4015

6061-O Aluminum Sheet: ASTM-B-209, AMS-4025

6061-T4 Aluminum Sheet: ASTM-B-209, AMS-4026

6061-T6 Aluminum Sheet: ASTM-B-209, AMS 4027

7075-T6 Aluminum Sheet: AMS-QQ-A-250/12, AMS-4045

7075-O ALCLAD Aluminum Sheet: ASTM-B-209

7075-O BARE Aluminum Sheet: AMS-QQ-A-250/12, AMS-4045

Aluminum Specular Lighting Sheet

| ALLOYS | SPECIFICATIONS |

|---|---|

| 1100 | AMS-4001, 4003, QQ-A-250/1 |

| 2014-BARE | AMS-4028, 4029 |

| 2014-ALCLAD | QQ-A-250/3 |

| 2024-BARE | AMS-4035,37, QQ-A-250/4 |

| 2024-ALCLAD | AMS-4040, 41, QQ-A-250/5 |

| 2124 | AMS-4101, QQ-A-250/29 |

| 2219 | AMS-4031, 94, 95, QQ-A-250/30 |

| 3003 | AMS-4006, 4008, QQ-A-250/2 |

| 5052 | AMS-4015, 16, 17, QQ-A-250/8 |

| 6013 | AMS-4347, 4216 |

| 6061 | AMS-4025, 26, 27, QQ-A-250/11 |

| 7050 | AMS-4050, 4201, BMS-7-194 |

| 7075-BARE | AMS-4044, 45, QQ-A-250/12 |

| 7075-ALCLAD | AMS-4048, 49, QQ-A-250/13 |

| 7178-BARE | QQ-A-250/14 |

| 7178-ALCLAD | QQ-A-250/15 |

| 7475 | AMS-4084, 4085 |

| Sizes: | .008 to .249 x R/W x R/L .250 to 18.00 x R/W x R/L |

Please note: Other alloys available upon request

* Special Tolerances Available

* Polishing & PVC Protected

Standard Specification of LM-2 Aluminium Sheet

Standards and specifications by country

| Specification | Alloy | Temper | Company |

|---|---|---|---|

| Europe | |||

| EN 2089/2395 | 2014A | T6(T62)/T4(T42) | |

| EN 2087/2088 | 2014A clad | T6(T62)/T4(T42) | |

| EN 4101 | 2024 | T4 | |

| EN 2090/2091/2703/4001 | 2024 clad cmq | T3/T4/T4(T42)/T351 | |

| EN 3474/3997/3998/3999 | 2024 cmq | T81/T3/T4(T42)/T351 | |

| EN 2694/EN 3341 | 6061 | T6(T62)/T4(T42) | |

| EN 4449/4450 | 7050 | T76/F(T762) | |

| EN 2696 | 7075 | T6(T62) | |

| EN 2092 | 7075 clad | T6(T62) | |

| EN 2802/3333 | 7475 | T761/F(T762) | |

| EN 2803/3332 | 7475 clad | T761/F(T762) | |

| France | |||

| AIR 9048.010/.030/ | 2014 | F(T42)/F(T62)/T4/ | |

| .020/.040/.050 | 2014 | T6/T451 | |

| AIR 9048.060/.080/.070/.090 | 2014 clad | F(T42)/F(T62)/T4/T6 | |

| AIR 9048.100/.110/.120 | 2024 | ||

| AIR 9048.130/.140 | 2024 clad | F(T42)/T3 | |

| AIR 9048.150 | 2618A | H28(T62) | |

| AIR 9048.170 | 2618A clad | H28(T62) | |

| AIR 9048.190/.200 | 5086 | O, H111/H22, H32 | |

| AIR 9048.210/.220/.230/.240 | 6061 | O, H111(T42)/T4/ O, H111(T62)/T6 | |

| AIR 9048.260/.270 | 7075 | T6/T76 | |

| AIR 9048.280 | 7075 clad | T6 | |

| AIR 9048.290 | 7475 | T76 | Boeing |

| Germany | |||

| W.-Nr. 3.1254 | 2014A | T4, T6 | |

| W.-Nr. 3.1354 | 2024 | O(T42), T3 | |

| W.-Nr. 3.1364 | 2024 clad | O(T42), T3 | |

| W.-Nr. 3.3214 | 6061 | O(T62), T6 | |

| W.-Nr. 3.4364 | 7075 | T6 | |

| W.-Nr. 3.4374 | 7075 clad | O(T62), T6 | |

| W.-Nr. 3.4377 | 7475 clad | T76 | |

| UK | |||

| BS L16/17 | 1200 | H4/O | |

| BS L156/157/158*/159* | 2014A | ||

| 158*/159* | 2014A clad | (T42)(T62) | BAE Systems |

| BS L163/164/165 | 2014A clad | T3/F(T42), T4/T6 | |

| BS L166*/167* | 2014A clad | F(T42), T4/T6 | |

| BS L109/110 | 2024 clad | T3/F(T42) | |

| DTD5070 | 2618A clad | T6 | |

| BS L59/60/61 | 3103 | H6/H2/O | |

| BS L80/81 | 5251 | O/H6 | |

| BS L113 | 6082 | T4, T6 | |

| BS L88 | 7075 clad | T6 | |

| USA | |||

| AMS QQ-A-250/3 | 2014 clad | O, T4, T6 | |

| AMS QQ-A-250/4 | 2024 | O, T3 | |

| AMS 4037 | 2024 | T3 | |

| AMS QQ-A-250/5 | 2024 clad | O, T3 | |

| AMS 4041 | 2024 clad | T3 | |

| AMS QQ-A-250/30 | 2219 | O(T62), T31(T81), T37(T87) | |

| AMS QQ-A-250/2 | 3003 | O, H14 | |

| AMS 4347 | 6013 | T4 | |

| AMS 4216 | 6013 | T6 | |

| AMS 4025/4026/4027 | 6061 | O, F, T4, T42, T45, T6, T62, T651 | |

| AMS QQ-A-250/12 | 7075 | O, T6, T73 | |

| AMS QQ-A-250/24 | 7075 | T76 | |

| AMS QQ-A-250/13 | 7075 clad | O, T6, T73 | |

| AMS QQ-A-250/26 | 7075 clad with 7011 | T76 | |

| AMS QQ-A-250/25 | 7075 clad with 7072 | T76 | |

| European Standard | BS (OLD) | USA (AA) | GERMANY (DIN) | ISO | IS | Canadian |

|---|---|---|---|---|---|---|

| EN AW-1050 A | 1E | 1050 | Al99.5 | Al99.5 | 19500, 19501 | 1 S |

| EN AW-1070 A | – | 1070 | Al-99.7 | Al-99.7 | 19700 | – |

| EN AW-1100 | IC | 1100 | Al-99.0 | Al-99.0 | 19000 | 2 S |

| EN AW-2011 | FC1 | 2011 | AlCuBiPb | AlCu6BiPb | – | 28S |

| EN AW-2014 | HE15 | 2014 | AlCuSiMn | AlCu4SiMg | 24345 | B26S |

| EN AW-2024 | – | 2024 | AlCuMg2 | AlCu4Mg1 | – | 24 S |

| EN AW-3003 | N3 | 3003 | AlMnCu | AlMn1Cu | 31000 | 3 S |

| EN AW-3103 | – | 3103 | – | AlMn1 | – | – |

| EN AW-6101A | E91E | 6101 | E AlMgSi 0.5 | E AlMgSi(A) | 63401 | D50S |

| EN AW-6005 | – | 6005 | AlMgSi0.7 | AlSiMg | 62400 | C51S |

| EN AW-6351 | HE30 | 6351 | AlMgSi1 | AlSiMg0.5Mn | 64430 | B51S |

| EN AW-6060 | – | 6060 | AlMgSi 0.5 | AlMgSi | – | – |

| EN AW-6061 | HE20 | 6061 | AlMgSiCu | AlMg1SiCu | 65032 | 65S |

| EN AW-6063 | HE9 | 6063 | AlMgSi0.5 | AlMg0.7Si | 63400 | 50S |

| EN AW-6082 | HE30 | 6351 | AlMgSi1 | AlSi1MgMn | 64430 | B51S |

LM-2 Aluminium Sheet Sizes

| Sizes (mm) | Theoretical Mass KG/sheet |

|---|---|

| 2000 X 1000 X 0.5 | 2500 X 1250 X 0.5 |

| 2000 X 1000 X 0.7 | 2500 X 1250 X 0.7 |

| 2000 X 1000 X 0.9 | 2500 X 1250 X 0.9 |

| 2000 X 1000 X 1.2 | 2500 X 1250 X 1.2 |

| 3000 X 1500 X 1.2 | 2000 X 1000 X 1.6 |

| 2500 X 1250 X 1.6 | 3000 X 1500 X 1.6 |

| 2000 X 1000 X 2.0 | 2500 X 1250 X 2.0 |

| 3000 X 1500 X 2.0 | 2500 X 1250 X 2.5 |

| 2.79 | 4.36 |

| 3.91 | 6.10 |

| 5.02 | 7.85 |

| 6.74 | 10.46 |

| 15.01 | 8.93 |

| 13.95 | 20.09 |

| 11.16 | 17.44 |

| 25.11 | 21.80 |

LM-2 Aluminium Sheet Weight Chart

Width: 1.000 mm | Length: 2.000 mm

| Product | Thickness | Weight |

|---|---|---|

| LM-2 Aluminium Sheet | 0,30 mm | 0,810 Kg/m2 |

| LM-2 Aluminium Sheet | 0,40 mm | 1,080 Kg/m2 |

| LM-2 Aluminium Sheet | 0,50 mm | 1,350 Kg/m2 |

| LM-2 Aluminium Sheet | 0,60 mm | 1,620 Kg/m2 |

| LM-2 Aluminium Sheet | 0,70 mm | 1,890 Kg/m2 |

| LM-2 Aluminium Sheet | 0,80 mm | 2,160 Kg/m2 |

| LM-2 Aluminium Sheet | 0,90 mm | 2,430 Kg/m2 |

| LM-2 Aluminium Sheet | 1,00 mm | 2,700 Kg/m2 |

| LM-2 Aluminium Sheet | 1,20 mm | 3,240 Kg/m2 |

| LM-2 Aluminium Sheet | 1,40 mm | 3,780 Kg/m2 |

| LM-2 Aluminium Sheet | 1,50 mm | 4,050 Kg/m2 |

| LM-2 Aluminium Sheet | 1,60 mm | 4,320 Kg/m2 |

| LM-2 Aluminium Sheet | 1,80 mm | 4,860 Kg/m2 |

| LM-2 Aluminium Sheet | 2,00 mm | 5,400 Kg/m2 |

| LM-2 Aluminium Sheet | 2,20 mm | 5,940 Kg/m2 |

| LM-2 Aluminium Sheet | 2,50 mm | 6,750 Kg/m2 |

| LM-2 Aluminium Sheet | 3,00 mm | 8,100 Kg/m2 |

| LM-2 Aluminium Sheet | 4,00 mm | 10,800 Kg/m2 |

| LM-2 Aluminium Sheet | 5,00 mm | 13,500 Kg/m2 |

| LM-2 Aluminium Sheet | 6,00 mm | 16,200 Kg/m2 |

| LM-2 Aluminium Sheet | 10,00 mm | 27,000 Kg/m2 |

| LM-2 Aluminium Sheet | 12,00 mm | 32,400 Kg/m2 |

| LM-2 Aluminium Sheet | 15,00 mm | 40,500 Kg/m2 |

| LM-2 Aluminium Sheet | 20,00 mm | 54,000 Kg/m2 |

LM-2 Aluminium Sheet Chemical Composition

| % | |

|---|---|

| Copper | 0.7 – 2.5 |

| Magnesium | 0.30 max |

| Silicon | 9.0 – 11.5 |

| Iron | 1.0 max |

| Manganese | 0.5 max |

| Nickel | 0.5 max |

| Zinc | 2.0 max |

| Lead | 0.3 max |

| Tin | 0.2 max |

| Titanium | 0.2 max |

| Aluminium | Remainder |

| Others: total | 0.50 max |

Aluminium LM-2 Sheet Mechanical Properties

LM2-M

| Chill Cast | Die Cast | |

|---|---|---|

| 0.2% Proof Stress (N/mm 2 ) | 90-130 | 130 |

| Tensile Stress (N/mm 2 ) | 150 -200 | 300 |

| Elongation (%) | 2-3 | 1-3 |

| Impact Resistance Charpy (Nm) | – | 2.9 |

| Brinell Hardness | 65-90 | 65-90 |

| Endurance Limit(5×10 7 cycles;N/mm 2 ) | 70-100 | 70-100 |

| Modulus of Elasticity (x10 3 N/mm 2 ) | 71 | 71 |

| Shear Strength (N/mm 2 ) | 200 | 200 |

The values shown are typical ranges for chill cast test bars produced to the requirement of B.S. 1490. Die cast values obtained on 6mm test bars. Those in heavier type are minimum specification values.

For most applications LM2 and LM24 are interchangeable, but LM2 has a slightly lower density, LM6 and LM20 would be betterthan LM2 in a corrosive environment, unless it can be protected by anodizing. LM2 has poor weldability and poor brazeability.

Aluminum Alloy Heat Treatment Temper Designations

Basic Aluminum Heat Treatment Designations

- F As Fabricated

- O Annealed

- H Strain Hardened

- W Solution Heat Treated

- T Solution Heat Treated

Heat Treating T Temper Codes

- T1 – Cooled from an elevated temperature shaping process and naturally aged to a substantially stable condition.

- T2 – Cooled from an elevated temperature shaping process, cold worked, and naturally aged to a substantially stable condition.

- T3 – Solution heat treated, cold worked, and naturally aged to a substantially stable condition.

- T4 – Solution heat treated, and naturally aged to a substantially stable condition.

- T5 – Cooled from an elevated temperature shaping process then artificially aged.

- T6 – Solution heat treated then artificially aged.

- T7 – Solution heat treated then overaged/stabilized.

- T8 – Solution heat treated, cold worked, then artificially aged.

- T9 – Solution heat treated, artificially aged, then cold worked.

- T10 – Cooled from an elevated temperature shaping process, cold worked, then artificially aged.

Additional digits may be used after the first T temper digit to indicate subsequent stress relieving by processes such as stretching, compressing, or a combination.

H Temper Strain Hardening Codes

- H1 – Strain hardened only

- H2 – Strain hardened and partially annealed

- H3 – Strain hardened and stabilized

- H4 – Strain hardened and lacquered or painted. This assumes that thermal affects from the coating process affect the strain hardening; seldom encountered.

LM-2 Packing Information of Aluminum plate :

Application of LM-2 Aluminium Sheet

LM-2 Aluminium Sheet is the most widely used form of Industrial Aluminium. LM-2 Aluminium Sheets find applications in various industries such as manufacturing cans and packages, transportation, home appliances, building and construction.

LM-2 Aluminium Sheet Applications