-

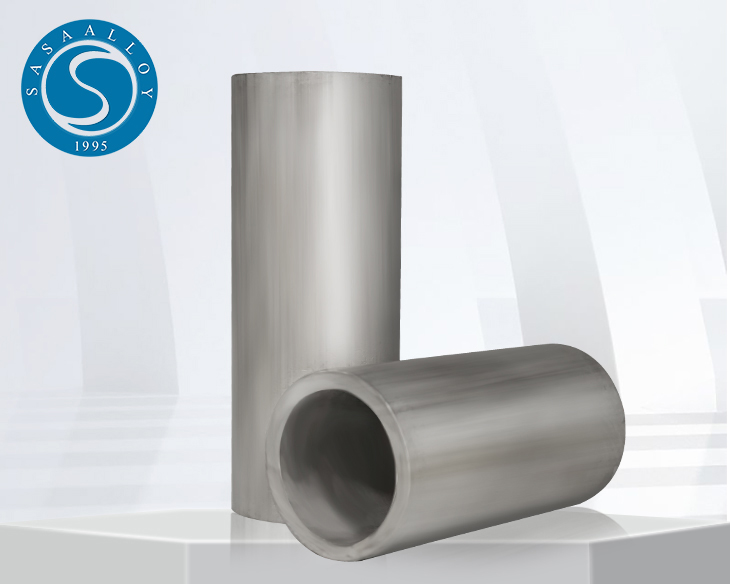

Incoloy 825 tubes also possess excellent mechanical properties, including high tensile strength and fatigue resistance, allowing them to withstand high-pressure environments without compromising structural integrity. Their thermal stability enables them to maintain their strength and performance ...Read more »

-

Inconel 600, 601, and 625 pipes find extensive applications in various industries such as aerospace, power generation, chemical processing, and oil and gas. 1. Aerospace Industry: Inconel alloy pipes are widely used in high-temperature components of aerospace engines, including nozzles, turbine ...Read more »

-

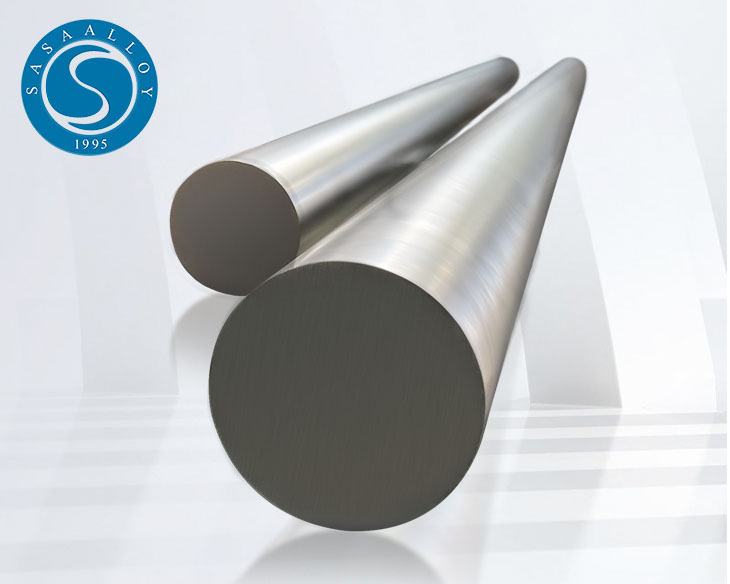

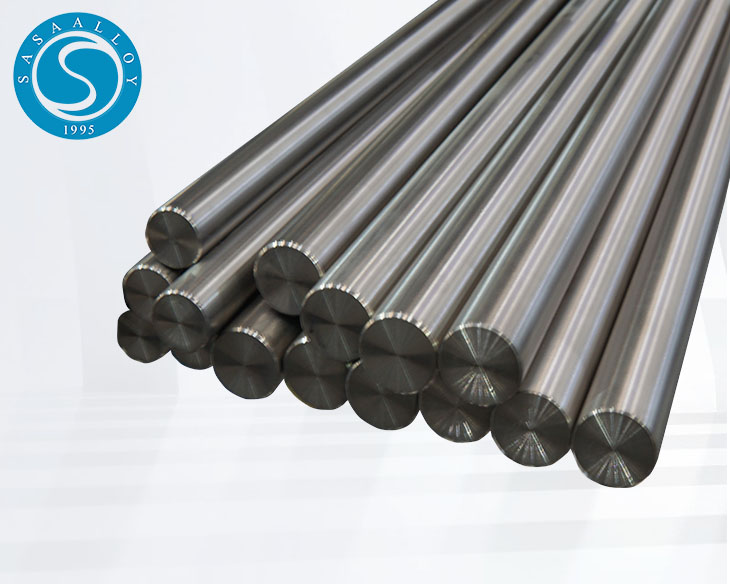

Inconel 600, 601, 625, and 718 round bars have various applications due to their unique properties. Equivalent Grades Of Inconel 600/601/625/718 round bars STANDARD WERKSTOFF NR. UNS GOST AFNOR JIS BS EN OR Inconel 600 2.4816 N06600 МНЖМц 28-2,5-1,5 NC15FE11M NCF 600 NA 13 NiCr15Fe ЭИ868 ...Read more »

-

Incoloy 800, 800H, and 800HT are nickel-iron-chromium alloys with good strength and excellent resistance to oxidation and carburization in high-temperature exposure. These nickel steel alloys are identical except for the higher level of carbon in alloy 800H, and the addition of up to 1.20 percent...Read more »

-

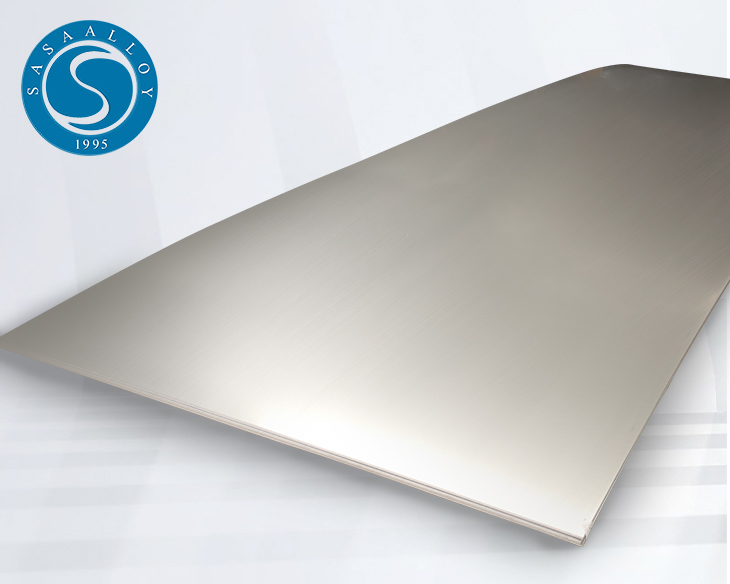

The thermal expansion coefficient of Inconel 601 sheet is approximately 13.1 x 10^-6 per °C (7.3 x 10^-6 per °F) in the temperature range of 20-1000 °C (68-1832 °F). This coefficient represents the amount of dimensional change that occurs in the material due to temperature variations. Inconel 601...Read more »

-

The chemical composition of Inconel 601 sheet typically consists of the following elements: Nickel (Ni): Approximately 58-63% Chromium (Cr): Approximately 21-25% Iron (Fe): Approximately 13-17% Aluminum (Al): Approximately 1-1.7% Manganese (Mn): Approximately 1% Silicon (Si): Approximately 0.5% C...Read more »

-

Inconel 600 Sheets offer several advantages over other materials in various applications. Some of the key advantages include: 1. Corrosion resistance: Inconel 600 Sheets exhibit exceptional corrosion resistance in a wide range of environments, including high-temperature oxidation, acids, alkaline...Read more »

-

Inconel 600 Sheets exhibit excellent corrosion resistance in a wide range of environments. They are known for their resistance to both oxidizing and reducing conditions, making them suitable for applications in various corrosive environments. Specifically, Inconel 600 Sheets are resistant to corr...Read more »

-

Inconel 601 bar, a nickel-chromium alloy, finds applications in various fields due to its exceptional properties. Here are some of the main fields of application for Inconel 600 bar: 1. Aerospace Industry: Inconel 601 bar is extensively used in aerospace applications that require high-temperature...Read more »

-

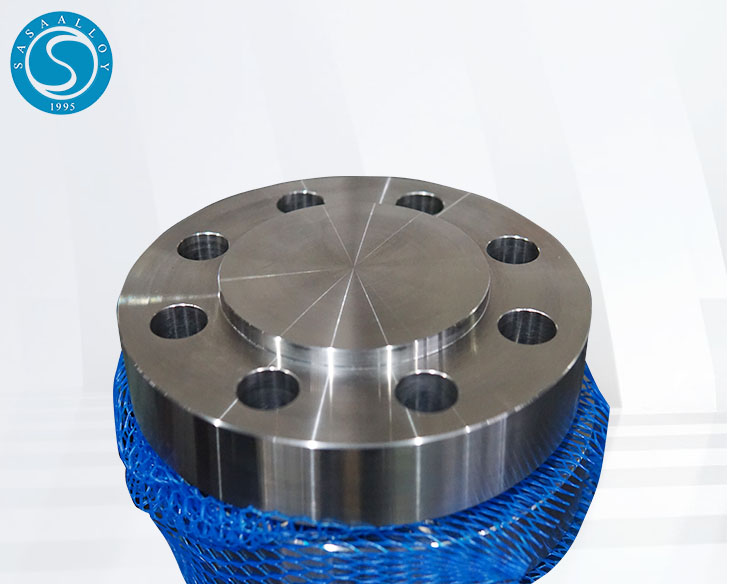

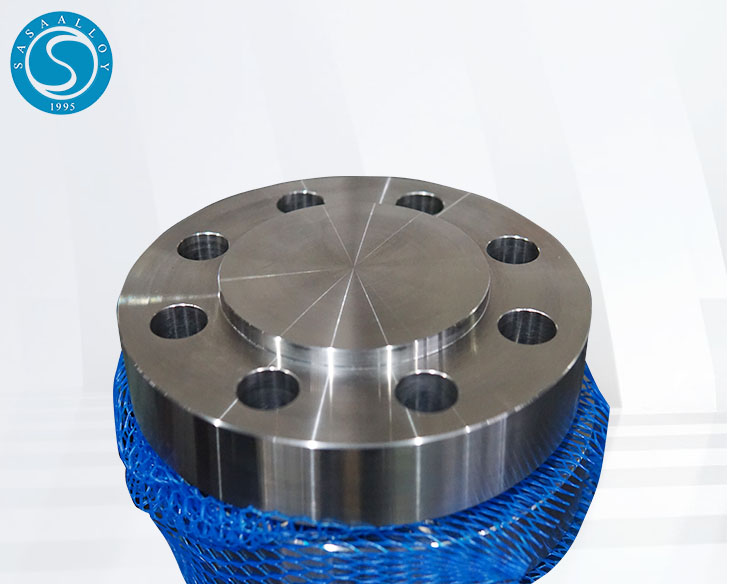

Inconel 600 superalloy flange is a material widely used in high temperature and high pressure conditions. It has excellent corrosion resistance, making it one of the most popular materials in industry. The following are five aspects of the excellent corrosion resistance of Inconel 600 superalloy ...Read more »

-

Inconel 600 bar, a nickel-chromium alloy, finds applications in various fields due to its exceptional properties. Here are some of the main fields of application for Inconel 600 bar: 1. Aerospace Industry: Inconel 600 bar is extensively used in aerospace applications that require high-temperature...Read more »

-

Inconel 600 sheet exhibits excellent mechanical properties, which contribute to its widespread use in various industries. Here are the typical mechanical properties of Inconel 600 sheet: 1. Tensile Strength: The tensile strength of Inconel 600 sheet is typically around 550 MPa (80,000 psi) in the...Read more »